Slickwater Technology Overview

Shale gas: This is a type of unconventional natural gas that originates from biogenic,thermogenic or mixed sources, and is trapped and preserved in dark-coloured or high-carbon mudstone that has high organic matter content and is mature. The gas is either adsorbed by the organic matter or stored in the fractures and matrix pores of the rock.

Hydraulic fracturing: Also known as fracturing or frac, this is a technique that improves the flow capacity of oil and gas reservoirs by using a high-pressure pump group on the surface to inject high-viscosity fluid into the well at a rate that greatly exceeds the formation’s absorption capacity, creating a high pressure near the bottom of the well. This pressure surpasses the formation stress and tensile strength of the rock near the bottom of the well, resulting in fractures in the formation. The fluid with proppant is continuously injected into the fracture to extend it and fill it with proppant. This way, a sand-filled fracture with sufficient length, height and width is formed after stopping pumping, which enhances the flow capacity of the oil and gas reservoir. This is a process technology that modifies the seepage characteristics of the reservoir,and is an important measure for increasing the production of oil and gas wells and injection of water injection wells.

Slickwater: This is a kind of fracturing fluid system for hydraulic fracturing of shale oil and gas reservoirs, and is one of the key fluids for shale gas development. It has been widely used in shale gas development due to its high efficiency and low-cost features, compared to the traditional gel fracturing fluid system.

Proppant: This refers to natural sand or artificial high-strength ceramic particles with certain particle sizes and gradation, and is a key material for fracturing operations.

1. Liquid preparation

We have an excellent service team that will arrive at the site as soon as they receive the production task. The service personnel will plan the placement of the pump group equipment according to the size of the site, and then determine how many chemicals to place in the remaining space area; they will lay dust-proof film (or tarpaulin) in the operation area, and lay dikes around the operation area.

After completing the chemical lifting, the personnel on the well will place them on-site in a standardized way, cover the operation area with a cover, set up a tent (to prevent equipment and chemicals from getting wet), place signs (MSDS-related content), and equip eye washers and fire extinguishers.

The service personnel will conduct an on-site slickwater experiment.

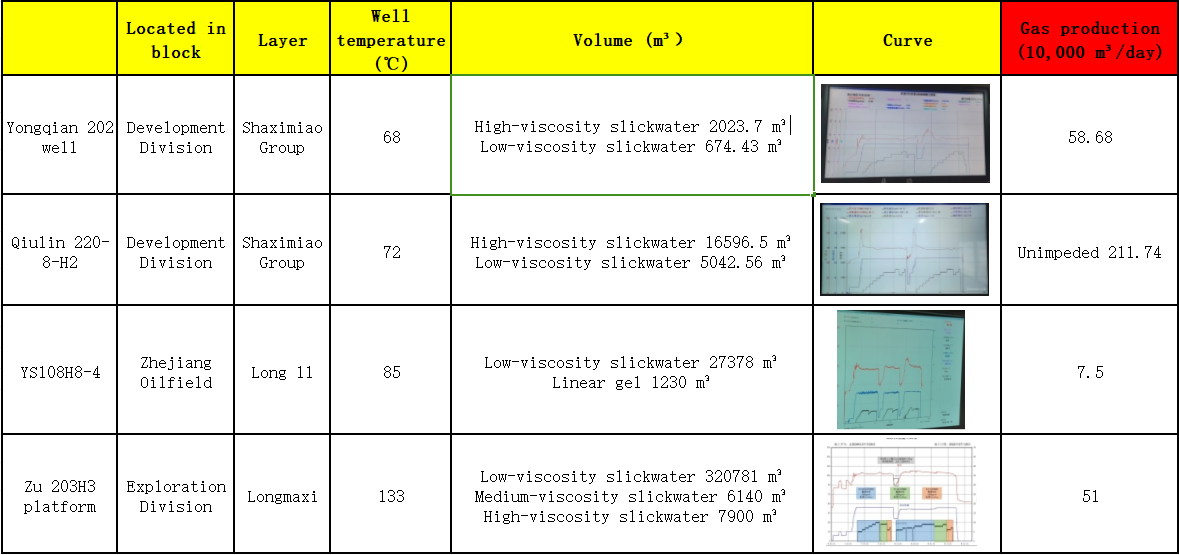

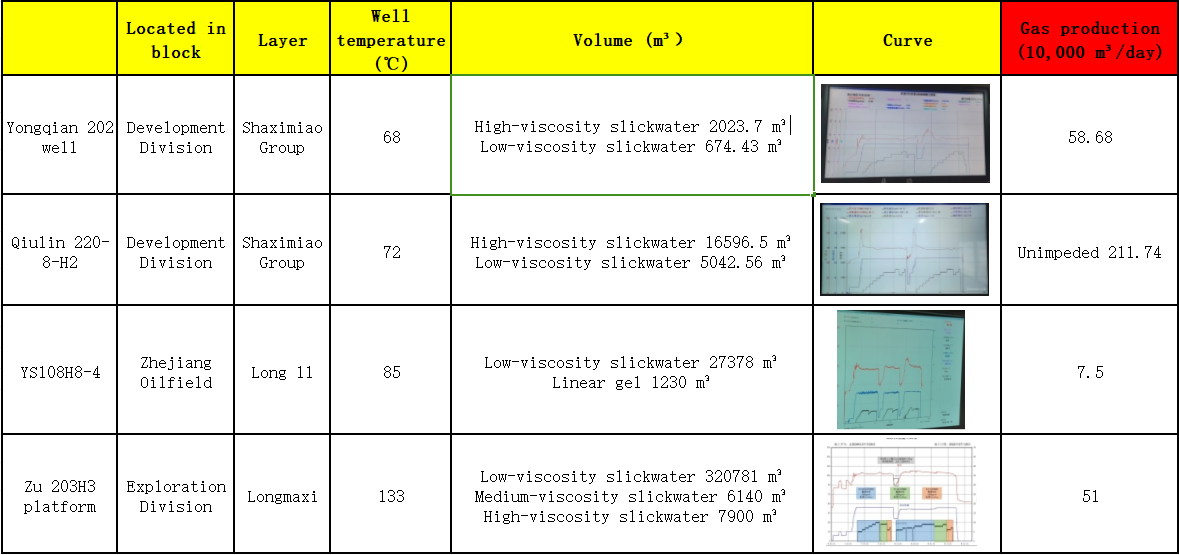

2、Wells applied

3、Feedback