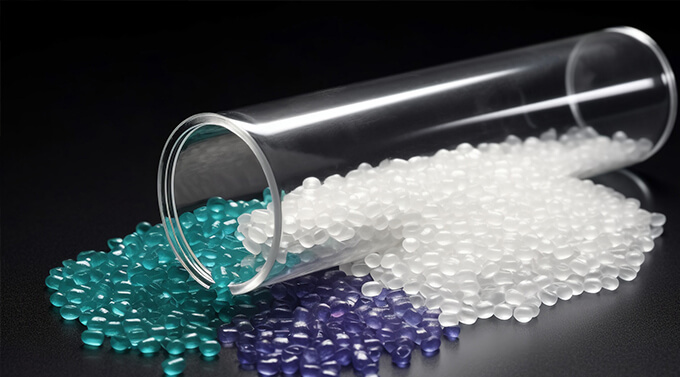

The novel anti-sedimentation fibres developed by our company utilize graphene nanomaterial technology to enhance the interaction of interfacial charges, enabling fibres and proppants to form a uniform and stable three-dimensional network structure in slickwater; overcome the gravity settling of proppants, improve the long-term structural stability performance of fibres and proppants, and form a stable structure that maintains a high height in the fracture for a long time.

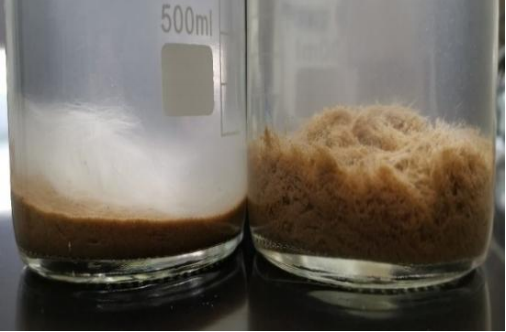

The state of proppants supported by ordinary fibres (left) and anti-sedimentation fibres (right)

Using the small physical size and multi-site adsorption features of fibre structure stabilizers,filling between fibres and proppants, strengthening the interaction between fibres and proppants; special lamellar structures increase the roughness of fibre surfaces, forming a similar wolf tooth stick structure, greatly enhancing the entanglement between fibres and proppants,achieving better sand carrying and sand prevention effects.

(1)Increase the amount of end fibres, reduce the backflow and regurgitation of proppants

Optimize the fibre dosage 70/140 quartz sand fibre 0.4%, and 40/70 ceramic sand fibre 0.5%,the higher the fibre dosage or the higher the closure stress, the larger the critical sand production flow rate. 70-140 mesh quartz sand: 0.4% fibre under 5MPa, its critical sand production flow rate is 40 times that of no fibre; 40-70 mesh ceramic sand: 0.5% fibre under 5MPa, its critical sand production flow rate is 48 times that of no fibre.

(2)Improve sand suspension ability

Fiber entanglement forms proppant clusters that play roles such as suspension, buoyancy,etc., rolling forward, and transporting proppants to farther places, in low-viscosity slickwater,0.4% fiber can increase proppant transport distance by 50%.

(3)Improve diversion ability

According to SY_T 6302-2019-Fracturing Proppant Diversion Ability Test Method, under the same conditions, adding fibre and its structure stabilizer increases diversion ability by 8.9% compared to the blank sample.

(4)Increase production

The effective volume of fracture support with full-course co-injection of fibre and its structure stabilizer increased by 38.4%, with relatively longer stable production time and higher production, and cumulative production increased by 22.5% in three years.